Tel: (86)-574-87934679 Email: sales@magbes.com

Ningbo Magbes Magnets Material Co.,Ltd

Tel:(86)-574-87934679

Fax:(86)-574-87934671

Email: sales@magbes.com

www.magbes.com

APPLICATION

Automotive Motor and EV Car Inverter

Energy-efficient Appliances

Medical Facility

Maglev Permanent Magnet Motor for Train

Copyright © 2018 Ningbo Magbes Magnets Material Co.,Ltd. All rights reserved. 浙ICP备18045592号-1 Powered by www.300.cn

|

Product Information: |

|

|

|

Product name |

Permanent NdFeB Disc Magnet, Nd Disc magnet, Neo Disc magnet, Rare earth Disc magnet |

|

|

Material |

Neodymium iron boron, Neo Magnet, Nd Magnet, Rare earth Magnet |

|

|

Grade & working Temperature |

Grade |

Max Operating Temperatures |

|

N35-N54 |

80°C (176°F) |

|

|

35M-52M |

100°C (212°F) |

|

|

35H-50H |

120°C (248°F) |

|

|

33SH-48SH |

150°C (302°F) |

|

|

28UH-45UH |

180°C (356°F) |

|

|

28EH-42EH |

200°C (392°F) |

|

|

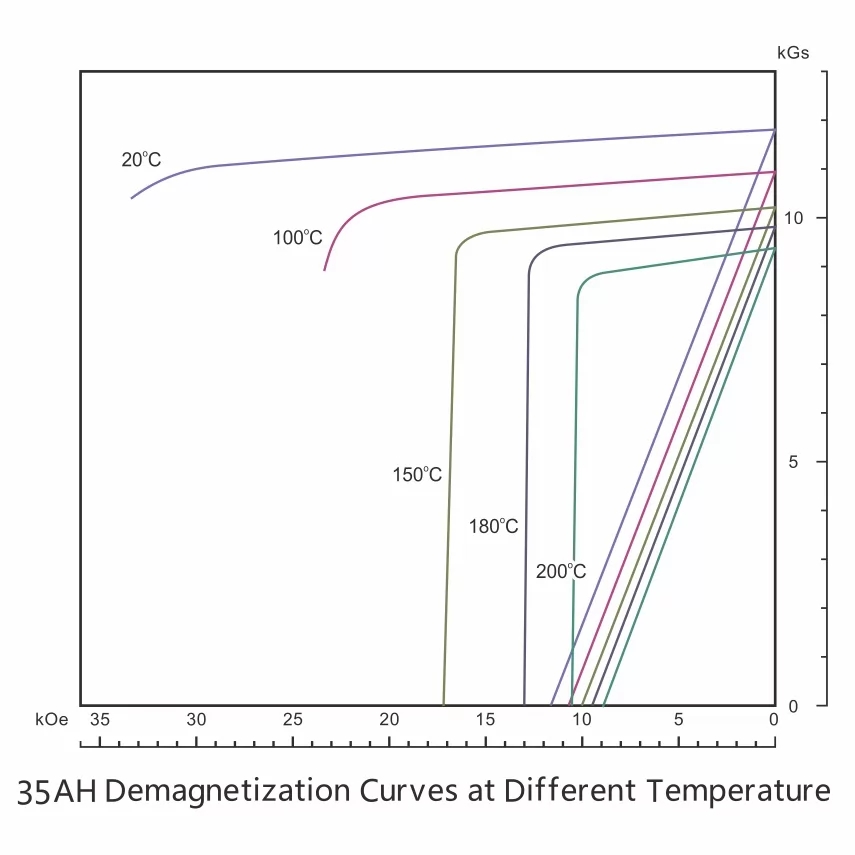

28AH-40AH |

230°C (446°F) |

|

|

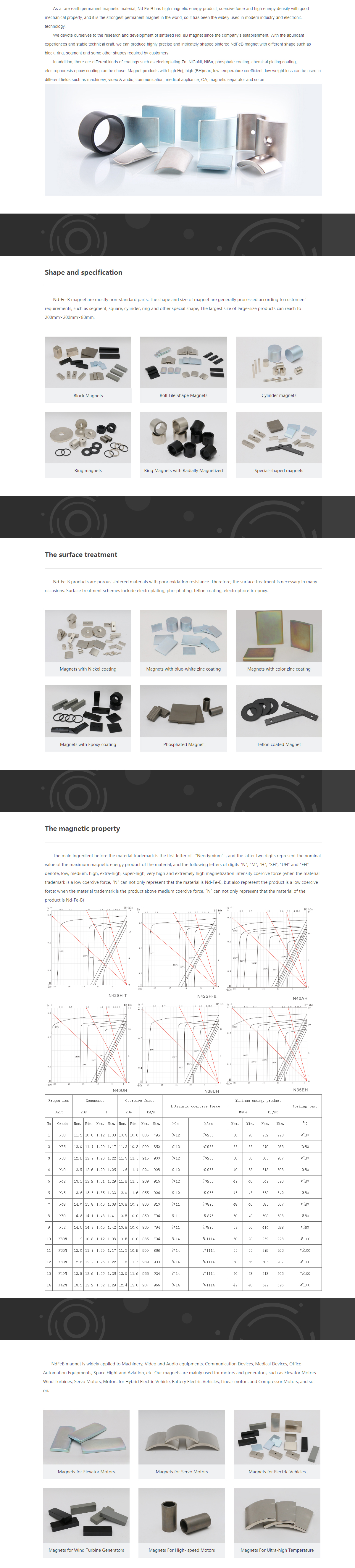

Shape |

Disc, Block or Rectangular or Cuboid, Ring, Cylinder, Arc and Irregular shape are also available |

|

|

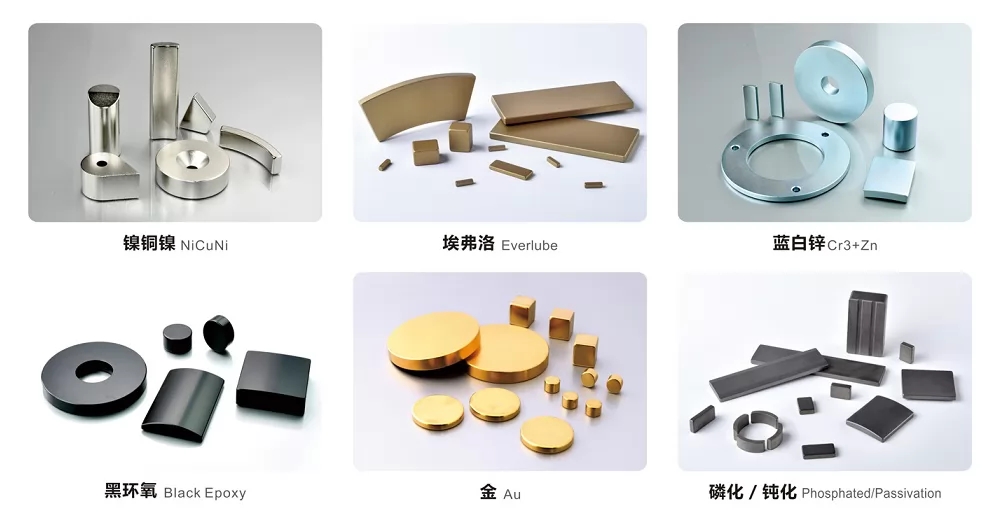

Coating |

Ni, Ni-Cu-Ni, Electroless Nickel, Zinc, Colored Zinc, Epoxy, Passivation, Phosphated, Parylene, Au, Ag, Sn etc. |

|

|

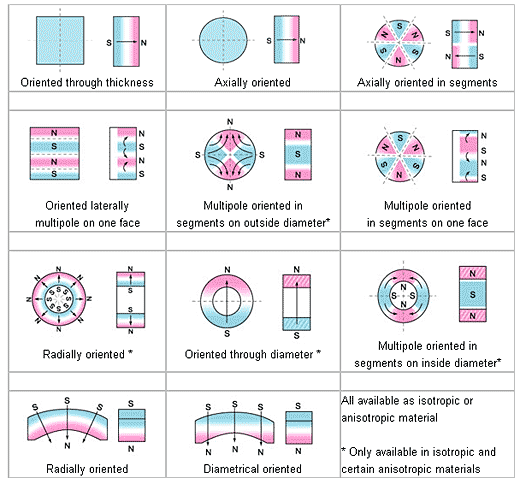

Magnetized direction |

Axially or Diametrical Magnetized, but Thickness, Multipoles and Radial magnetization are also available, Customized magnetization is welcome. |

|

|

Application |

Servo motor,Brushless motor, Linear Motor, Automotive Motor, HEV& EV motor, Robot Driving Motor, Inverter Compressor Motor , Rail Transit Traction Motor, Consumer Electronics, Wind turbine, Energy-saving Elevator, Loudspeaker, Magnetic switch, VCM, MRI, Magnetic separator, sensor etc. |

|

|

Certificate |

ISO9001, RoHS, REACH |

|

|

Packing |

Standard sea or air packing, such as carton, wooden box, pallet etc. |

|

|

Lead time |

7 days for samples, 15-20 days for mass production. |

|

|

Transportation |

All shipping methods are available: courier (TNT, DHL, FedEx, UPS), air or sea. |

|

Magnetic properties of Sintered NdFeB magnets:

|

Grade |

Remanence |

Coercive Force |

Intrinsic Coercive Force |

Max. energy product |

Max. |

|

Operating |

|||||

|

Temperature |

|||||

|

Br |

Hcb |

Hcj |

(BH ) |

Tw |

|

|

max |

|||||

|

mT |

kA/m |

kA/m |

kJ/m3 |

||

|

(kGs) |

(kOe) |

(kOe) |

(MGOe) |

||

|

N35 |

1170-1220 |

>= 868 |

>=955 |

263-287 |

80°C |

|

(11.7-12.2) |

( >= 10.9) |

( >= 12) |

(33-36) |

||

|

·N38 |

1220-1250 |

>=899 |

>=955 |

287-310 |

80°C |

|

(12.2-12.5) |

( >= 11.3) |

( >= 12) |

(36-39) |

||

|

N40 |

1250-1280 |

>= 907 |

>=955 |

302-326 |

80°C |

|

(12.5-12.8) |

( >= 11.4) |

( >= 12) |

(38-41) |

||

|

N42 |

1280-1320 |

>= 915 |

>=955 |

318-342 |

80°C |

|

(12.8-13.2) |

( >= 11.5) |

( >= 12) |

(40-43) |

||

|

N45 |

1320-1380 |

>= 923 |

>=955 |

342-366 |

80°C |

|

(13.2-13.8) |

( >= 11.6) |

( >= 12) |

(43-46) |

||

|

N48 |

1380-1420 |

>= 923 |

>=955 |

366-390 |

80°C |

|

(13.8-14.2) |

( >=11.6) |

( >= 12) |

(46-49) |

||

|

N50 |

1400-1450 |

>= 796 |

>=955 |

382-406 |

80°C |

|

(14.0-14.5) |

( >= 10.0) |

( >= 12) |

(48-51) |

||

|

N52 |

1430-1480 |

>= 796 |

>=876 |

398-422 |

80°C |

|

(14.3-14.8) |

( >= 10.0) |

( >= 11) |

(50-53) |

||

|

N54 |

1450-1510 |

>= 836 |

>=876 |

406-438 |

80°C |

|

(14.5-15.1) |

( >= 10.5) |

( >= 11) |

(51-55) |

||

|

33M |

1130-1170 |

>= 836 |

>= 1114 |

247-263 |

100°C |

|

(11.3-11.7) |

(>= 10.5) |

( >= 14) |

(31-33) |

||

|

35M |

1170-1220 |

>= 868 |

>= 1114 |

263-287 |

100°C |

|

(11.7-12.2) |

( >= 10.9) |

( >= 14) |

(33-36) |

||

|

38M |

1220-1250 |

>= 899 |

>= 1114 |

287-310 |

100°C |

|

(12.2-12.5) |

( >= 11.3) |

( >= 14) |

(36-39) |

||

|

40M |

1250-1280 |

>= 923 |

>= 1114 |

302-326 |

100°C |

|

(12.5-12.8) |

( >= 11.6) |

( >= 14) |

(38-41) |

||

|

42M |

1280-1320 |

>= 955 |

>= 1114 |

318-342 |

100°C |

|

(12.8-13.2) |

( >= 12.0) |

( >= 14) |

(40-43) |

||

|

45M |

1320-1380 |

>= 995 |

>= 1114 |

342-366 |

100°C |

|

(13.2-13.8) |

( >= 12.5) |

( >= 14) |

(43-46) |

||

|

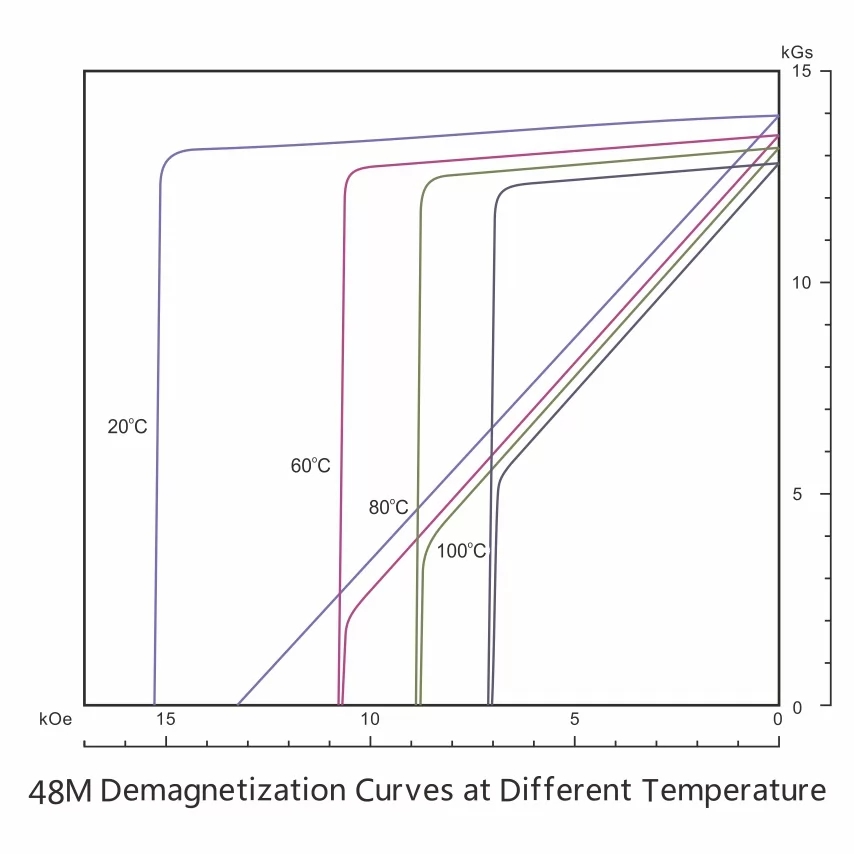

48M |

1360-1430 |

>= 1027 |

>= 1114 |

366-390 |

100°C |

|

(13.6-14.3) |

( >= 12.9) |

( >= 14) |

(46-49) |

||

|

50M |

1400-1450 |

>= 1033 |

>= 1114 |

382-406 |

100°C |

|

(14.0-14.5) |

( >= 13.0) |

( >= 14) |

(48-51) |

||

|

52M |

1420-1480 |

>= 1059 |

>= 1114 |

390-422 |

100°C |

|

(14.2-14.8) |

( >= 13.3) |

( >= 14) |

(49-53) |

||

|

35H |

1170-1220 |

>= 868 |

>= 1353 |

263-287 |

120°C |

|

(11.7-12.2) |

( >= 10.9) |

( >= 17) |

(33-36) |

||

|

38H |

1220-1250 |

>= 899 |

>= 1353 |

287-310 |

120°C |

|

(12.2-12.5) |

( >= 11.3) |

( >= 17) |

(36-39) |

||

|

40H |

1250-1280 |

>= 923 |

>= 1353 |

302-326 |

120°C |

|

(12.5-12.8) |

( >= 11.6) |

( >= 17) |

(38-41) |

||

|

42H |

1280-1320 |

>= 955 |

>= 1353 |

318-342 |

120°C |

|

(12.8-13.2) |

( >= 12.0) |

( >= 17) |

(40-43) |

||

|

45H |

1320-1360 |

>= 963 |

>= 1353 |

326-358 |

120°C |

|

(13.2-13.6) |

( >= 12.1) |

( >= 17) |

(43-46) |

||

|

48H |

1370-1430 |

>= 995 |

>= 1353 |

366-390 |

120°C |

|

(13.7-14.3) |

( >= 12.5) |

( >= 17) |

(46-49) |

||

|

50H |

1400-1450 |

>= 1027 |

>= 1274 |

374-406 |

120°C |

|

(14.0-14.5) |

( >= 12.9) |

( >= 16) |

(47-51) |

||

|

35SH |

1170-1220 |

>= 876 |

>= 1592 |

263-287 |

150°C |

|

(11.7-12.2) |

( >= 11.0) |

( >= 20) |

(33-36) |

||

|

38SH |

1220-1250 |

>= 907 |

>= 1592 |

287-310 |

150°C |

|

(12.2-12.5) |

( >= 11.4) |

( >= 20) |

(36-39) |

||

|

40SH |

1240-1280 |

>= 939 |

>= 1592 |

302-326 |

150°C |

|

(12.5-12.8) |

( >= 11.8) |

( >= 20) |

(38-41) |

||

|

42SH |

1280-1320 |

>= 987 |

>= 1592 |

318-342 |

150°C |

|

(12.8-13.2) |

( >= 12.4) |

( >= 20) |

(40-43) |

||

|

45SH |

1320-1380 |

>= 1003 |

>= 1592 |

342-366 |

150°C |

|

(13.2-13.8) |

( >= 12.6) |

( >= 20) |

(43-46) |

||

|

48SH |

1370-1430 |

>= 1011 |

>= 1592 |

358-390 |

150°C |

|

(13.7-14.3) |

( >= 12.7) |

( >= 20) |

(45-49) |

||

|

28UH |

1020-1080 |

>= 764 |

>= 1990 |

207-231 |

180°C |

|

(10.2-10.8) |

( >= 9.6) |

( >= 25) |

(26-29) |

||

|

30UH |

1080-1130 |

>= 812 |

>= 1990 |

223-247 |

180°C |

|

(10.8-11.3) |

( >= 10.2) |

( >= 25) |

(28-31) |

||

|

33UH |

1130-1170 |

>= 852 |

>= 1990 |

247-271 |

180°C |

|

(11.3-11.7) |

( >= 10.7) |

( >= 25) |

(31-34) |

||

|

35UH |

1180-1220 |

>= 860 |

>= 1990 |

263-287 |

180°C |

|

(11.8-12.2) |

( >= 10.8) |

( >= 25) |

(33-36) |

||

|

38UH |

1220-1250 |

>= 876 |

>= 1990 |

287-310 |

180°C |

|

(12.2-12.5) |

( >= 11.0) |

( >= 25) |

(36-39) |

||

|

40UH |

1240-1280 |

>= 899 |

>= 1990 |

302-326 |

180°C |

|

(12.5-12.8) |

( >=11.3) |

( >= 25) |

(38-41) |

||

|

42UH |

1290-1350 |

>= 963 |

>= 1990 |

318-350 |

180°C |

|

(12.9-13.5) |

( >=12.1) |

( >= 25) |

(40-44) |

||

|

28EH |

1040-1090 |

>= 780 |

>= 2388 |

207-231 |

200°C |

|

(10.4-10.9) |

( >= 9.8) |

( >= 30) |

(26-29) |

||

|

30EH |

1080-1130 |

>= 812 |

>= 2388 |

223-247 |

200°C |

|

(10.8-11.3) |

( >= 10.2) |

( >= 30) |

(28-31) |

||

|

33EH |

1130-1170 |

>= 876 |

>= 2388 |

247-271 |

200°C |

|

(11.3-11.7) |

( >= 10.5) |

( >= 30) |

(31-34) |

||

|

35EH |

1170-1220 |

>= 876 |

>= 2388 |

263-287 |

200°C |

|

(11.7-12.2) |

( >= 11.0) |

( >= 30) |

(33-36) |

||

|

38EH |

1220-1250 |

>= 899 |

>= 2388 |

287-310 |

200°C |

|

(12.2-12.5) |

( >= 11.3) |

( >= 30) |

(36-39) |

||

|

40EH |

1260-1320 |

>= 939 |

>= 2388 |

302-334 |

200°C |

|

(12.6-13.2) |

( >= 11.8) |

( >= 30) |

(38-42) |

||

|

28AH |

1040-1090 |

>=787 |

>= 2624 |

207-231 |

230°C |

|

(10.4-10.9) |

( >= 9.9) |

( >= 33) |

(26-29) |

||

|

30AH |

(26-29) |

>=819 |

>= 2624 |

223-247 |

230°C |

|

(10.8-11.3) |

( >= 10.3) |

( >= 33) |

(28-31) |

||

|

33AH |

1130-1170 |

>= 843 |

>= 2624 |

247-271 |

230°C |

|

(11.3-11.7) |

(>= 10.6) |

( >= 33) |

(31-34) |

||

|

35AH |

1170-1240 |

>= 876 |

>= 2786 |

263-295 |

230°C |

|

(11.7-12.4) |

(>= 11) |

( >= 35) |

(33-37) |

||

|

Note: |

|||||

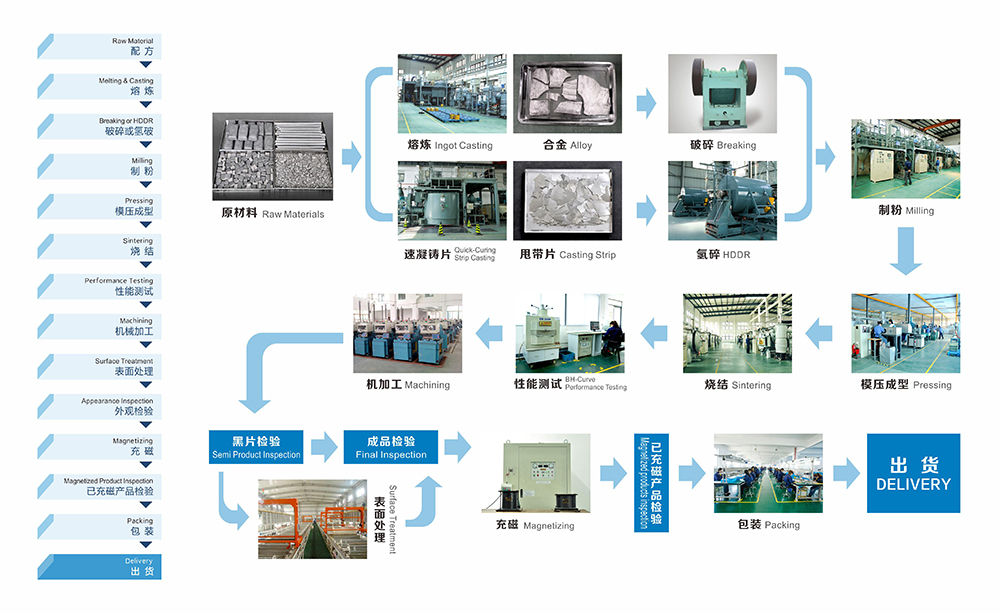

Production flow of Permanent NdFeB Magnet:

Thermal Characteristics

|

|

Thermal Expansion Coeff. |

Maximum Operating Temp |

Curie Temp |

Thermal Conductivity |

|

%/°C |

°C (°F) |

°C (°F) |

kcal/m-h-°C |

|

|

N |

-0.12 |

176°F (80°C) |

590°F (310°C) |

7.7 |

|

M |

-0.12 |

212°F (100°C) |

644°F (340°C) |

7.7 |

|

H |

-0.11 |

248°F (120°C) |

644°F (340°C) |

7.7 |

|

SH |

-0.10 |

302°F (150°C) |

644°F (340°C) |

7.7 |

|

UH |

-0.10 |

356°F (180°C) |

662°F (350°C) |

7.7 |

|

EH |

-0.10 |

392°F (200°C) |

662°F (350°C) |

7.7 |

The Thermal Characteristics listed above are values commonly associated with each magnet's grade or material. Actual performance in your application may vary with other factors, including the shape of the magnet, the Permeance Coefficient or load line, and how it is used in a circuit.

Available coatings for Sintered NdFeB magnet and Plating Characteristics

|

|

||||

|

Surface |

Coating |

Thickness (Microns) |

Color |

Resistance |

|

Passivation |

|

1 |

Silver Grey |

Temporary Protection |

|

Nickel |

Ni+Ni |

10-20 |

Bright Silver |

Excellent against Humidity |

|

Ni+Cu+Ni |

||||

|

Zinc |

Zn |

8-20 |

Bright Blue |

Good Against Salt Spray |

|

C-Zn |

Shinny Color |

Excellent Against Salt Spray |

||

|

Tin |

Ni+Cu+Sn |

15-20 |

Silver |

Superior Against Humidity |

|

Gold |

Ni+Cu+Au |

10-20 |

Gold |

Superior Against Humidity |

|

Copper |

Ni+Cu |

10-20 |

Gold |

Temporary Protection |

|

Epoxy |

Epoxy |

15-25 |

Black, Red, Grey |

Excellent Against Humidity |

|

|

||||

|

|

||||

|

Ni+Cu+Epoxy |

||||

|

Zn+Epoxy |

||||

|

Parylene |

parylene |

5-25 |

Grey |

Excellent against Humidity,Salt Spray, Superior Against Solvents |

Dimension Range / Nominal Tolerance

|

Ring Magnet |

Outer Diameter (mm) |

Inner Diameter (mm) |

Thickness (mm) |

|

Maximum |

220 |

80 |

50 |

|

Minimum |

2.6 |

1.8 |

0.5 |

|

Tolerance |

±0.1 |

±0.1 |

±0.1 |

|

Block Magnet |

Length (mm) |

Width (mm) |

Thickness (mm) |

|

Maximum |

250 |

180 |

50 |

|

Minimum |

2.0 |

1.5 |

0.5 |

|

Tolerance |

±0.1 |

±0.1 |

±0.1 |

|

Disc Magnet |

Diameter (mm) |

Thickness (mm) |

|

Maximum |

220 |

50 |

|

Minimum |

1.2 |

0.5 |

|

Tolerance |

±0.1 |

±0.1 |

Segment & other irregular shapes can be manfactured according to customer's sample or drawing

Magnetization Directions of Permanent Magnets